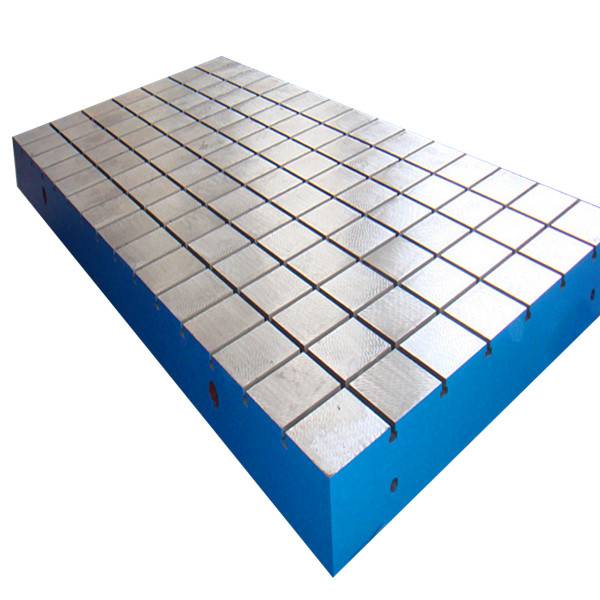

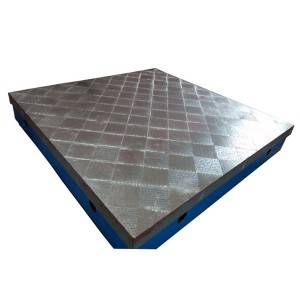

T slotted pā hao ili

T slotted pā hao ili

Hoʻohana ʻia kā mākou T-slotted hao / papa papahele e like me nā kumu paʻa a pololei i nā ʻoihana ʻenekinia no ka hoʻohālikelike ʻana, ka hoʻonohonoho ʻana, ke ana pololei ʻana, ka hana hui, nā hana kau no ka hui ʻana o nā lako, nā hana hou a me nā mea ʻē aʻe. nā papa moe no nā wili wili, gantry milling/drilling machines etc. Hoʻohana ʻia lākou e like me nā moena hoʻāʻo e kākoʻo i nā ʻenekini, nā motika, nā compressors, nā pamu, nā kiwi, nā mīkini nui, nā pahu hoʻoili a i ʻole nā mīkini ʻoihana nui ʻē aʻe.

Ma kāu mau koi, e hōʻike mākou i nā kiʻi e hōʻike ana i nā hoʻolālā kikoʻī e like me kā mākou mau noiʻi loea no kāu loiloi.Hoʻonohonoho mau ʻia kēia mau ʻāpana T-slotted hao / kila i nā nui like ʻole e like me nā koi o ka pūnaewele e loaʻa ai nā papa i kāu mau papa hana.

Nā hiʻohiʻona o kā mākou papa papahele T-slotted:

1. Mea mea he kiʻekiʻe-ikaika, kiʻekiʻe-density a kokoke grained hina hina hao i loaʻa ma Grade o GG-20, GG-25 a i ole GG-30 no ko makou T-slotted hoolei papahele hao papa.Hiki ke hoʻohana ʻia nā mea ʻē aʻe e like me ka hao nodular a i ʻole ke kila hoʻoheheʻe ʻia inā noi;

2. ʻO ke ʻano ribbed & cored o nā papa papahele hao T-slotted e hāʻawi i ka rigidity premium a me ka ikaika.Hiki ke hāʻawi ʻia ka hale paʻa e like me kāu noi.Ma muli o kāu mau koi o ka hiki ke hoʻouka kaumaha a me ka palena o ka lumi no ka hoʻokomo ʻana i nā papa papahele hao T-slotted, e hāʻawi mākou i nā hoʻolālā o nā papa i loko o kahi ʻano paʻa a i ʻole nā papa ʻāpana;

3. ʻO ka paʻakikī ka mea maʻamau no ka GG-25 hina hina i ka laulā o HB170-240.Inā noi ʻia ka paʻakikī kiʻekiʻe ma nā papa papahele T-slotted, e hoʻohana mākou i nā mea ʻē aʻe e like me ke kila hoʻolei a i ʻole ka hao nodular.Loaʻa ka pololei o ka palahalaha o ka ʻili ma ke ʻano he Grade I, II a i ʻole III e like me ka DIN 876 Standardad i kūpono kūpono no nā noi kikoʻī kiʻekiʻe e like me ka pā moe no ka CNC boring mill a i ʻole nā noi i manaʻo nui ʻia e like me ke kumu no ka hui / wehe ʻana i nā lako. .Hiki ke kiʻi ʻia ka pololei ʻoi aku ka palahalaha ma ka ʻoki lima ma kāu noi.ʻO ka roughness maʻamau ka Ra 3.2 μm i loaʻa me ka CNC kiʻekiʻe-wikiwiki kaʻina hana.Hiki ke hoʻokō ʻia ka haʻahaʻa haʻahaʻa e like me Ra 1.6 μm ma ke kaʻina wili i kāu noi;

4. ʻO ka ʻae ākea o nā T-slots ma nā papa he H12 a hiki nō hoʻi iā H7 a i ʻole H8 ma ke noi ʻana ma kā mākou mau papa papahele hao T-slotted.ʻO ka maʻamau, hāʻawi ʻia nā T-slots like me ka longitudinal kuhikuhi, akā hiki ke hāʻawi ʻia nā T-slots tilting to the longitudinal direction ma ke noi;

5. Hiki ke hāʻawi ʻia nā ʻāpana hoʻohui ma nā ʻaoʻao a pau o nā papa papahele hao T-slotted ma ke noi e hui pū i nā ʻāpana o nā papa i kahi pā nui;

6. Hoʻolakoʻia nā papa hoʻolālā a me nā heleuma, aiʻole nā papa hoʻolālā a me nā pā kila me nā papa i mea hoʻokomo no nā mea hoʻokomo.ʻAʻole hiki ke hāʻawi ʻia nā puʻu wai hoʻoheheʻe haʻalulu ma ke noi;